I am able to scan the DL PDF417 barcodes and I see that driverLicense object is set within Barcode object. However for some states (Eg. FL, NC) the driverLicense object is NULL. When I checked the valueFormat in Barcode object it is set to 12 (Barcode.DRIVERLICENSE) for working scenario and set to 7 (Barcode.TEXT) for non-working scenario. Thankfully, new driver’s licenses also have PDF417 barcodes on them, and in North America, follow specifications laid out by the American Association of Motor Vehicle Administrators (AAMVA). These barcodes are small, error resistant, and can encode a lot of information. BarCode - the license contains a bar code. 2d Code - the license contains a two dimensional bar code. May 01, 2019 Florida Driver License and Identi cation Card 2D Barcode (PDF417) from Card Back. Sample Class E Florida Driver License Example PDF 417 decodes as: This example displays a typical Class E driver license, with sample data populated. Refer to the following page for full detail of the 2D barcode possible contents.

The PDF417 barcode is a two-dimensional (2D), high-density symbology capable of encoding text, numbers, files and actual data bytes. This FAQ provides information and answers to commonly asked questions.

- PDF417 Overview

- Generating and Printing PDF417 Barcodes

- Macro-PDF417

PDF417 Barcode Overview

Large amounts of text and data can be stored securely and inexpensively when using the PDF417 barcode symbology. The printed symbol consists of several linear rows of stacked codewords. Each codeword represents 1 of 929 possible values from one of three different clusters. A different cluster is chosen for each row, repeating after every three rows. Because the codewords in each cluster are unique, the scanner is able to determine what line each cluster is from.

PDF417 Error Correction Levels

PDF417 uses Reed Solomon error correction instead of check digits. This error correction allows the symbol to endure some damage without causing loss of data. AIM standards recommend a minimum error correction level of 2. The error correction level depends on the amount of data that needs to be encoded, the size and the amount of symbol damage that could occur. The error correction levels range from 0 to 8. The chart below indicates the number of error correction codewords that are added to the printed symbol and AIM recommendations for the EC level.

Fig. 1: AIM recommended EC levels

| EC Level | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| EC Codewords Generated | 2 | 4 | 6 | 8 | 16 | 32 | 64 | 128 | 512 |

| Data Codewords | 1-40 | 41-160 | 161-320 | 321-863 | |||||

| Data Bytes Encoded | 1-56 | 57-192 | 193-384 | 385-1035 |

X and Y Dimensions

- The X dimension is the width of the narrowest bar in a printed codeword. The Y dimension is the height of each row within the PDF417 symbol. The PDF417 barcode is usually printed at an X to Y ratio of 1:2 to 1:5, with 1:3 being the most popular. By lowering the ratio, a significant amount of space can be saved; however, some scanners cannot read X to Y ratios of less than 1:3. Most scanners, such as the IDAutomation PDF417 2D USB Scanner, read PDF417 barcodes well at 1:3. When creating symbols with more than 10 columns, IDAutomation recommends using a ratio of 1:4 or 1:5.

Row and Column Limits

- The number of rows and columns can be selected, allowing the symbol to be created in various forms. However, the PDF417 barcode symbol is limited to 30 columns and 90 rows. Keep in mind when selecting columns, only the number of data columns in the symbol are being selected. The normal PDF417 barcode symbol has two row start columns and two row stop columns. Truncated PDF417 contains only two row start columns. Some scanners and decoders cannot dependably read over 20 columns.

Truncated PDF417

- A truncated PDF417 symbol uses less area than the normal PDF417 barcode. By selecting this option, the right hand side of the symbol is removed or truncated. This option should be used primarily in a clean environment, since it is more susceptible to damage.

Generating and Printing

The IDAutomation PDF417 Barcode Font and Encoder is a collection of encoders and components that generate PDF417 symbols as graphics or as a font. All of our PDF417 products were created from ISO/IEC 15438. IDAutomation also offers new patent-pending Native Barcode Generators for JavaScript, Crystal Reports and Microsoft Access that create PDF417 without any plug-ins or fonts. Barcode Integration Guides are also available that offer one or more integration options. These options may be examined to determine the best implementation method. A few of the guides offered include the following:

Measuring X & Y Dimensions of a Printed Barcode

Barcode products generate images according to the pixels of the target device thereby creating an image difference. Consequently, it may be necessary to check the X or Y dimensions. Images and symbol sizes may differ slightly with various screen resolutions and printers.

To find the printed Y dimension

- Print a PDF417 barcode symbol with exactly 10 rows.

- To obtain 10 rows, choose 5 columns, an error correction of 2 and print the text of “IDAutomation.com, Inc. PDF417 ActiveX Control” with binary encoding.

- Measure the distance from the top of the symbol to the bottom and divide by 10.

- Example: if 10 rows measured .425 inches, then .425″ divided by 10 equals .0425″, giving a Y dimension of 42 mils per row.

To find the printed X dimension

- Measure 6 or more columns, but do not include the start and stop columns in the measurement, divide this number by the number of columns measured, then by 17. The result is the X dimension.

- Example: if 6 columns measure .875″, divide .875″ by 6, which equals .14583″ per column. Because the X dimension width of each column is 17, take the .14583″ and divide it by 17, which equals .00857″, which is about 8 mils.

Compaction Modes & Amount of Data Encoded

It is recommended to limit the amount of data in each 2D barcode symbol to 800 characters or less, using 20 columns or less. Although the specification states that “up to 1100 bytes or 1800 ASCII characters can be encoded in a PDF417 symbol,” it is not usually achievable. The amount of data that can be encoded will vary depending upon the type of data, the compaction type, the error correction level chosen and the limitation of the scanner being used. For example, in text compaction mode, the amount of compaction varies due to mode switching between different types of characters, such as between numbers, upper case, lower case and punctuation. In addition, many PDF417 CCD scanners do not reliably read more than 800 to 850 characters and some scanners have limits of only 300 characters.

If it is necessary to encode more than 800 characters, IDAutomation recommends using Macro PDF mode or multiple separate symbols. In the best-case scenario, using the text encoding mode of the IDAutomation PDF417 Forms Control with the IDAutomation 2D Barcode Scanner, up to 1200 characters were successfully encoded and retrieved.

Each codeword represents 1 of 929 possible values, which allows data to be compacted into the codewords to save space. PDF417 has three data compaction modes: binary, text and numeric. Binary compaction encodes actual bytes of data; text mode encodes most characters on the U.S. keyboard (ASCII 32-126) including ASCII 9 (the tab function) and ASCII 13 (the return function). Numeric compaction encodes only numbers, is rarely used and not available in all products due to calculation limitations. The chart below provides more detail about these modes.

| Compaction Type (Numeric Value) | Data Encoded | Maximum Compaction |

| Binary Compaction (0) | ASCII – 0 to 255 | 1.2 bytes per codeword |

| Text Compaction (1) | ASCII – 9,10,13 & 32-126 | 2 characters per codeword |

| Numeric Compaction (2) | only numbers 0-9 | 2.9 digits per codeword |

To encode the most amount of data into the smallest possible symbol:

The amount of data compaction will vary depending upon the type of data that is being encoded and the error correction level chosen. If the scanner supports it, smaller symbols may be obtained by performing any of the following:

- Use TEXT compaction mode.

- Decrease the error correction level to 2.

- Increase the number of columns to the largest possible size.

- Decrease the X dimension to the smallest possible size the scanner will read.

- Turn on truncation, which decreases the symbol size by two columns.

- Choose an X to Y ratio of 1:3.

Encoding Functions (such as Tabs and Returns)

PDF417 allows ASCII functions to be easily encoded for various operations such as encoding tabs and returns. Normally, these characters are not visible unless an application is used such as IDAutomation’s Barcode Scanner ASCII String Decoder, which displays these hidden functions as tags. In all IDAutomation products, the tilde (~) may be used to encode ASCII functions. For example; ~009 is used to encode a tab and ~013 encodes a return. In many development environments, Chr or Char may also be used to encode the ASCII value directly. For example, the programming examples below encode “PDF” <tab> 417:

Java: DataToEncode= “PDF” + (char)9 + “417”;

Visual Basic & VBA: DataToEncode= “PDF” & ChrW(9) & “417”

Crystal Reports VB & SSRS: DataToEncode= “PDF” & Chr(9) & “417”

Encoding Data for FedEx® applications:

FedEx uses a combination of Code 128 and PDF417 barcodes on packing slips to automate delivery and tracking. FedEx publishes a FedEx Ground Multicode Barcode Label Guide and a Barcode and Label Layout Specification Guide that should always be examined when implementing FedEx label applications.

The following is a summary of the PDF417 barcode requirements for FEDEX label printing:

- The PDF Security Level or Error Correction Level must be set to 5.

- The X dimension must be 10mils (.010″ or .0254 CM) with an X to Y ratio (or N Dimension) of 5. To achieve this with the PDF417 Font and Encoder, print with IDAutomation2D N5 or the IDAutomationPDF417n5 font at 12 points.

- The number of columns should be set to 10.

- The entire message should not exceed 350 characters.

- The quality of the symbol must be ANSI grade “A”. The IDAutomation 2D Barcode Scanner’s Print Quality Assessment may be used as a guide for this requirement.

- The data encoded must begin with: [)>RS01GS where RS is ASCII 30 and GS is ASCII 29. In IDAutomation products, if ApplyTilde if set to “True” or “1,” the format ~ddd is used to specify the ASCII code of the character to be encoded. These characters cannot be viewed or printed and therefore it may not appear to be present, unless an application is used such as IDAutomation’s Barcode Scanner ASCII String Decoder.

NOTE: The code supplied below is an example and not a complete solution. More information about structuring messages to meet FedEx label specifications may be found at FedEx’s website.

Java Example:

Visual Basic Example:

Tilde Processing of Control Characters

IDAutomation PDF417 barcode products all support the format ~ddd to specify the ASCII code of the character to be encoded, which allows easy encoding of GS, RS and EOT from the command line.

For example, the following string:

“[)>”+RS+ “01”+GS+ “0133626”+GS+ “840”+GS+”002″+GS…

May also be encoded with this string:

[)>~03001~02996336260000~029840~029002~029….

Before implementing the printed PDF417 barcodes for FedEx applications, it is recommended to verify the symbol with the Print Quality Assessment test of the IDAutomation 2D Barcode Scanner or another suitable verifier. Additionally, the 2D Scanner together with the Free Barcode Scanner ASCII String Decoder may be used to view the non-printable RS, GS and EOT lower ASCII functions, which will appear as tags. To perform the test, simply open the Barcode Scanner ASCII String Decoder and scan a MaxiCode symbol with the Image Reader.

Encoding International & Extended Characters

It is possible to scan and encode international and extended characters, provided the instructions below are followed:

- Encode the data using binary encoding. This option encodes all ASCII data, byte-by-byte. For information about encoding UTF-8 and Unicode characters, refer to the UTF-8 and Unicode Encoding FAQ.

- Scan the data with a scanner capable of reading and decoding binary data. With some scanners, this is only possible via the serial interface option with data bits set to 8N. Normally, keyboard wedges and USB scanners do not support extended characters above ASCII 128, and only scan characters that are actually on the keyboard. Contact the scanner vendor for more information; some of the scanner’s internal settings may have to be modified. For information about reading UTF-8 and Unicode characters, refer to the UTF-8 and Unicode Encoding FAQ.

Reading PDF417 Barcodes

The most common method of reading barcodes is with a PDF Capable Barcode Scanner such as the IDAutomation 2D Barcode Scanner with PQA, which reliably reads the IDAutomation PDF417 Font when printed as small as 3 points, which is an X-dimension of only 5 mils. Most of the hand-held barcode imagers recommended by IDAutomation perform keyboard emulation and receive power from the USB port, so that no external power supply is needed. When a barcode symbol is read using keyboard emulation, the data appears at the cursor as if it had been typed in from the keyboard. In some cases, it may be desired to have the scanner trigger a form or action in an application. IDAutomation has documented easy methods of accomplishing this in the USB Barcode Scanner Application Integration Guide.

Verifying PDF417 Barcodes

Printed symbols may be easily verified with the Print Quality Assessment test found in the IDAutomation 2D Barcode Scanner. The quality assurance test will grade the symbol and report the X dimension, Y dimension and any possible problems. The report below was generated when scanning the PDF symbol to the right with PQA enabled:

MacroPDF417 Barcodes

MacroPDF417 is an implementation of PDF417 capable of encoding very large amounts of data into multiple PDF417 barcodes. These multiple barcodes are then scanned by a MacroPDF enabled scanner, which reassembles them into one string of data. Each MacroPDF barcode segment shares a file ID with the other segments, which make up the entire barcode sequence. If the file ID is not the same, the scanner will assume that each of the segments belong to a different barcode sequence. In order for the scanner to reassemble the barcode in the correct order, each segment of the barcode must have a unique segment index, starting at zero. This unique segment index allows the scanner to know how to reassemble the barcode segments, and allows reading symbols in non-sequential order.

2D products that generate MacroPDF417 symbols:

- .NET Windows Forms Controls– used to create and print barcodes from local .NET applications.

- ASP.NET Server Control – Custom Server Control designed to be used in ASP.NET Web Applications

- ActiveX Barcode Control & DLL – this is the best product to use for Microsoft® Access reports and Visual Basic 6. It may also be used in C++.

- Barcode Image Generator – generates images one at a time or from the command prompt.

- Java Barcode Packages– these packages include JavaBeans, Servlets, Class Libraries & Applets that may be used on any operating system with a Java Virtual Machine including Linux, UNIX and Mac.

- Streaming Barcode Server for IIS – adds barcode streaming generation capability to Microsoft Internet Information Server.

Macro PDF417 Example

| First Segment: MacroPDFEnable = True MacroPDFFileID = 237 MacroPDFSegmentIndex* = 0 MacroPDFLastSegment = False | Second Segment: MacroPDFEnable = True MacroPDFFileID = 237 MacroPDFSegmentIndex* = 1 MacroPDFLastSegment = True |

Macro PDF417 Properties

- Macro PDF Enable – A Boolean indicating that this barcode is part of a MacroPDF417 sequence.

- Macro PDF File ID – Assigns a file ID to the MacroPDF barcode. Each barcode in the MacroPDF sequence must have the same file ID assigned to it. Default is 0; valid options are 0-899.

- Macro PDF Segment Index – The index number of this MacroPDF barcode in relation to the set. Default is 0; valid options are 0-99998; * each barcode in the MacroPDF sequence must have a unique segment index, starting at zero and incrementing thereafter by 1.

- Macro PDF Last Segment – A Boolean indicating that this is the final barcode in the MacroPDF sequence.

If assistance is needed, please contact IDAutomation.

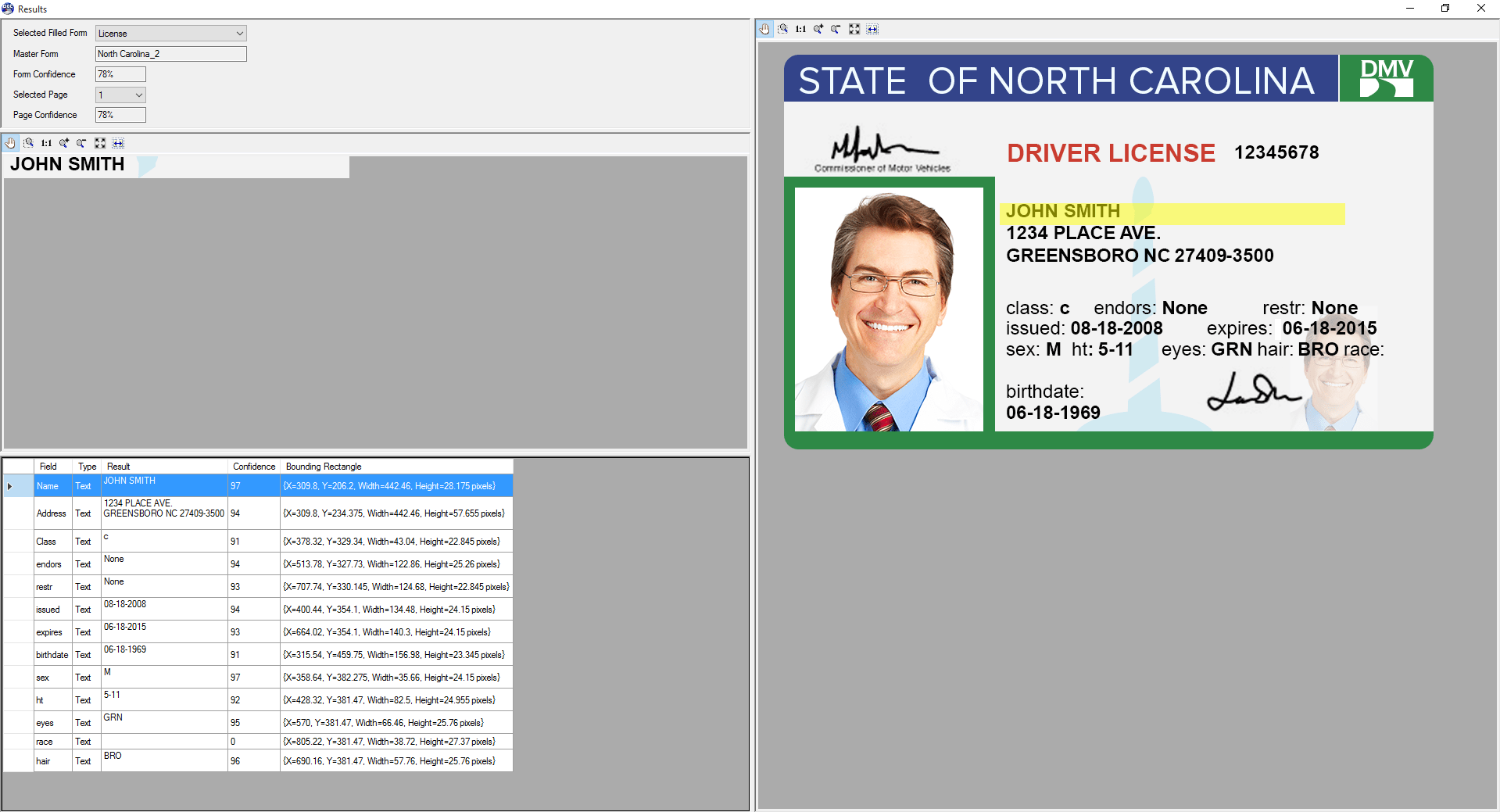

ClearImage Driver License Reader SDK

Extract personal identification and reference data from US and Canada Driver Licenses and ID cards. Read the PDF417 and 1D barcodes from identification documents around the world using optimized image enhancement algorithms.

Just a few code lines extract driver license data C#VBC++PHPVBScript See more examples ...- Read PDF417 barcodes from poor quality US and International ID documents

- Extract personal information from US/Canada Driver Licenses and ID Card

- Extract personal information from US Military CAC cards

- Uniformly represent data from various formats of Driver Licenses/ID Cards

- Respond timely to Driver License standards changes and individual state's practices

US/Canada Driver License / ID Information

- Name: First, Middle, Last, Suffix

- User Address

- Date of birth

- Physical data: weight, height, eye and hair color

- License data: id, date issue, date expires

- ANSI data in XML output

Image source

- PDF and TIF single/multi-page

- PDF Data/Image/MRC content

- JPEG, PNG, GIF, BMP, etc.

- Windows and .NET Bitmap, .NET Stream

- Base64-encoded image

- Bi-tonal, grayscale or color

Runtime Environment

- Windows Workstation: 7, 8, 10

- Windows Server: 2008, 2008 R2, 2012, 2012 R2, 2016, 2019

- Virtual Machine, Cloud Deployment (including Amazon EC2, Azure VM and Azure Web Apps)

- Web Server. Works with Web API Barcode Reader

Free for developers

- No charge for Software Development Kit (SDK)

- Support for any number of developers

- Zero-cost before production deployment

Languages and Environment

- API: COM, .NET.

- Projects: 32-bit or 64-bit or AnyCPU.

- Languages: C#, VB, Java, C++, VB6, Delphi, PHP, VBScript, Java Script, Python, Perl, Ruby etc.

Easy Evaluation

- Download SDK to load your images in ClearImage Demo. Read barcodes. See Driver License data immediately.

- Or just submit your images to Online Barcode Reader

Rapid Development

- Create your own working project in couple of hours using :

- The example projects in Visual Studio C#, C++.

- Code examples for C#, VB, C++, Delphi, PHP, VB Script

- Intuitive API requires no knowledge of barcodes or imaging. No obscure parameters to specify.

Unattended Production Operations

Fully automated and reliable barcode data extraction from high volume of images is essential for real-life IT environment. ClearImage Barcode Recognition SDK is a result of Inlite's 20 years experience to address requirements of thousands production installations. This resulted in achieving:

High Recognition Rate

Multiple recognition algorithms compensate for damages introduced during document handling and scanning/faxing. Engine takes full advantage of grayscale and color scanning. Inlite's design methodology is a continuous algorithm improvement toward 100% recognition rate of customer images.

High Performance

High volume image-based system demands optimum recognition speed. Barcode recognition often performed within 30 mSec. Multi-threading supports full utilisation of multi-core server processing.

Reliable operations

Non-stop unattended operations demand the highest level of reliability. ClearImage Barcode recognition is proven in thousands of high-volume production installations around the world.

Why choose Inlite for your imaging technology?- 22 years addressing mission critical imaging needs for OEM and enterprise customers

- Continuing algorithm improvements deliver up to date, reliable technology.

- Thousands of installations, and millions of images processed daily at the largest enterprises attest to the quality and performance of the technology

- Inlite's personal attention and dedicated engineering support enable your developers to rapidly deliver successful solutions

Read how our customers describe the relationship with Inlite...

Inlite Research has been a tremendous partner to work with. Our new application required some special functionality related to barcode capture and the Inlite team walked us through the entire process and allowed us to deliver a solution ahead of schedule.Jason Case, VP-Sales, Ambir Technology, USA

All Star ID develops advanced visitor management applications for enterprises and government institutions. Our solution performance depends on the ClearImage DL/ID Reader, which provides us with a unified presentation of data fields from the various driver licenses that we encounter. We were able to quickly integrate the software and get it working. Inlite has helped us understand how to architect our software for maximum performance. They have responded quickly to all of the issues that we raised.

Rodney Newton,All-Star Identification Systems, Inc., USA

To identify product you need see ClearImage Barcode Readers Comparison or contact Inlite sales.Reader 2D | Driver License |

|---|---|

| Barcode types | |

| Code 39, 128 and other popular 1D | |

| PDF417 | |

| DataMatrix | |

| QR | |

| Postal barcodes | |

| Patch document separator | |

| Operational features | |

| Targeted Barcode Reader™ support | |

| Optimized for typical DL/ID damages | |

| Decode Driver Licenses data |

| DL/ID Reader SDK | Server / VM Runtime | ||||

| ClearImage Driver License Reader |

|

| |||

Reader 2D | Driver License |

|---|---|

| Barcode types | |

| Code 39, 128 and other popular 1D | |

| PDF417 | |

| DataMatrix | |

| QR | |

| Postal barcodes | |

| Patch document separator | |

| Operational features | |

| Targeted Barcode Reader™ support | |

| Optimized for typical DL/ID damages | |

| Decode Driver Licenses data |

Licenses are perpetual and never expire.

A license is required for production use on each physical computer,

each instance of virtual machine, and each cloud VM instance.

All licenses include one year of support (including software updates)

Maximum processing speed:

| Deployment Environment | Workstation License |

|---|---|

| Windows 7, 8, 10 | 25 pages-per-minute |

| Windows Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019 | 5 pages-per-minute |

| Virtual Machine and Cloud VM | 5 pages-per-minute |

Licenses are perpetual and never expire.

A license is required for production use on each physical computer,

each instance of virtual machine, and each cloud VM instance.

All licenses include one year of support (including software updates)

Licenses are perpetual and never expire.

A license is required for production use on each physical computer,

each instance of virtual machine, and each cloud VM instance.

All licenses include one year of support (including software updates)

Each WABR license requires at least one of the following:

- • ClearImage Reader 1D Server license

- • ClearImage Reader 2D Server license

- • ClearImage Reader 1D + 2D Server license

- • ClearImage Driver License Reader Server license

Licensing Policy highlights:

- One Runtime License enables the production software to operate on one workstation or one physical server, or one virtual machine, or one cloud VM instance

- Server Licenses can be operated on any Windows physical or virtual computer.

- Workstation Licenses are intended for Windows 7, 8, 10 running on one computer; they are limited to 25 pages per minute. Unlimited pages per minute require the Server License. Operating Workstation License on a Windows Server, VM or Cloud VM processing will limit processing to 5 pages per minute. A page is an image in a single-image file (JPG, BMP, PNG, etc.) or a single page in a TIFF or PDF file.

- The number of users, images or cores are not limited by the license.

- Unless otherwise arranged with Inlite, the licenses are perpetual and the fees are paid one time in advance.

- The license includes support and software updates for one (1) year. Support for additional years is available.

Drivers License Barcode Format Codes For Free

All prices are shown in US$. The shopping cart will show prices in your local currency. Prices are subject to change without notice.Please contact us, if you want to:

- Pay by Paypal, bank wire or check

- Issue purchase order, or get a formal quotation

- Order more than 10 licenses or have special requirements

- Use ClearImage with Azure Web Apps